Wooden greenhouses do not lose their popularity for many years. They have a number of advantages and are made from available materials. Consider the advantages and disadvantages of wooden greenhouses, their varieties and designs, terms of operation, as well as how to make inexpensive greenhouse construction of wood yourself.

Do-it-yourself construction of greenhouses and hotbeds from wood

Many owners of land when building a greenhouse with their own hands for the frame of the structure choose a tree.

Did you know? The largest greenhouse complex of the Russian Federation is located in Moskovsky (Novomoskovsky administrative district of Moscow).

Advantages and disadvantages of wooden frame greenhouses

- Greenhouse buildings made of wood have several advantages:

- Availability. This material is easy to purchase and select the required sizes.

- Environmental friendliness. In any conditions, the tree does not emit harmful substances that can affect crops grown in the greenhouse. When the wooden frame serves its purpose, it is easy and simple to dispose of it without consequences for the environment - burn it, and use the ash as a natural fertilizer.

- Cost. Wood will cost much less than metal profiles or supporting structures made of PVC.

- Ease of assembly. Almost every household has a wood tool, which does not require any special skills. All you need is a saw, a hammer, a tape measure and nails.

- The disadvantages of such wooden structures are as follows:

- The need for service. In order for the wooden building to last longer, it must be tinted and impregnated with special solutions. In addition, wooden greenhouses need more thorough annual disinfection.

- Fire hazard. Wood belongs to well burning materials.

- Fragility. Wood is a less strong material than metal.

- Shading. Wide beams and boards will give an extra shadow.

Varieties of wooden greenhouses and greenhouses

Wooden greenhouses are portable or stationary. By its location, a greenhouse can be:

- self - freestanding design;

- adjoining - One wall is replaced by a building wall or fence.

By type of cover, a greenhouse building can be:

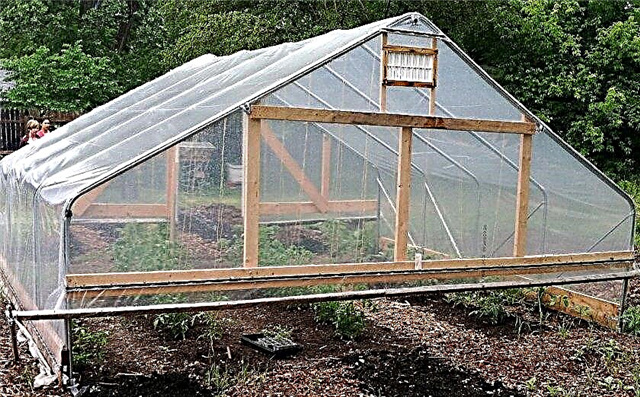

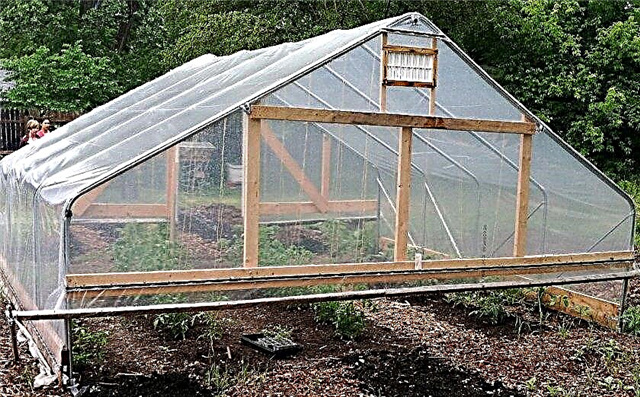

- Film. Polyethylene film is cheap and easily covers the structure, it is easy to repair. It gives almost no load on the frame. However, it does not last long, and it does not have the best thermal insulation and light transmission. The longest life of modern films is 4 seasons.

- Non woven. Non-woven materials are very similar in quality to the film.

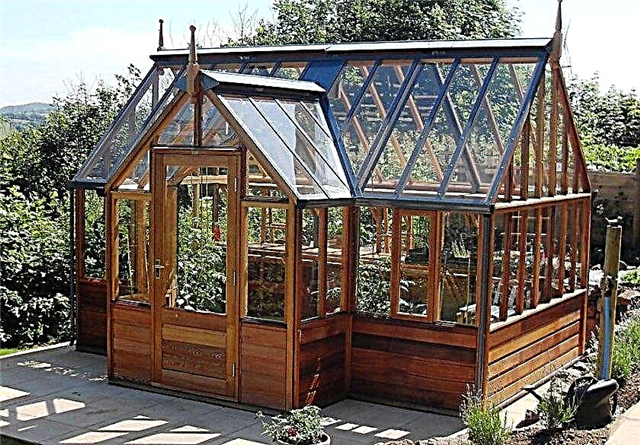

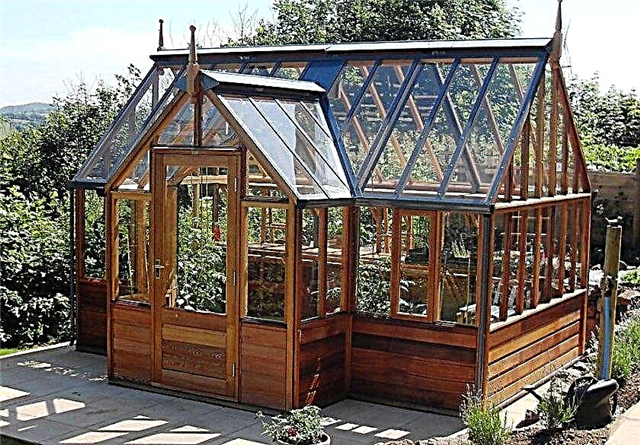

- Glass. Glass is environmentally friendly, it let in sunlight better than anyone, but it can break, and sometimes there is more light than necessary. It has a weight and a load on the foundation. For it, you can use used glass from window frames.

- Polycarbonate Polycarbonate transmits light well and has good thermal insulation properties, is easy to cut, does not ignite. The service life is 20 years. It is considered the best, but it also has the highest price.

Wooden greenhouse life

Different factors can affect how long a wooden structure lasts. Without treatment, the tree will last at least 4–5 years. Special treatment with antiseptics can significantly extend this period. It is possible to replace an expensive and not always ecological chemical product with the help of drying oil or used engine oil, which is heated to + 60 ° C. It is optimal to process the framework 2 times a year in the off-season.

Important! Be sure to do an antiseptic treatment against decay of the ends of the structure that will dig into the ground.

Then the wooden frame will last at least 10 years. The durability of the building is very dependent on the material used. Larch and oak will serve best, as they are the most durable and resistant to decay. Pine, spruce, hornbeam, beech, teak are also suitable. We should not forget about the covering material of the structure and change it in time.

Varieties of designs and drawings

There are many design options for greenhouses. Consider the most used of them in practice, with the exception of the usual gable version.

Arched

The arch-shaped structure has a semicircular or other circular shape in the upper part in the section. It is mounted from arcs that are connected to each other at regular intervals by horizontal elements. This is a rather advantageous form of construction, and the material consumption will be small. It is quite stable and durable. Due to the shape in the form of arcs, the rays of the sun, regardless of the time of day, fall at right angles to the coating of the structure, which contributes to better lighting inside the building than, for example, in gable structures. In addition, plants can grow to a greater height than in simpler greenhouses. The disadvantage of the arched construction is the fact that at home it is not easy to make an element in the form of an arch from wood.

Due to the shape in the form of arcs, the rays of the sun, regardless of the time of day, fall at right angles to the coating of the structure, which contributes to better lighting inside the building than, for example, in gable structures. In addition, plants can grow to a greater height than in simpler greenhouses. The disadvantage of the arched construction is the fact that at home it is not easy to make an element in the form of an arch from wood.

Did you know? Medieval inquisition considered the creator of the German greenhouses Albert Magnus the sorcerer for violating the natural change of seasons and banned the construction of such structures.

This requires certain skills. The arched type is not quite suitable for growing seedlings, because it does not make it possible to harden plants. In winter, due to the fact that snow cannot slide freely from such a roof, snow accumulations can occur that can cause the roof to break.

Domed

The shape of this design looks unusual. It is great for seismically hazardous areas. In addition, it is quite economical in terms of consumption of building materials. It must be well insulated and sealed at the joints. Such greenhouses are mounted from triangular-shaped cladding elements, so the cost and complexity of installing such a structure is higher than other, simpler, greenhouse structures. But they accumulate heat well and provide a favorable internal microclimate.

Single slope

Greenhouses with one slope look like a half of the house. Often, such structures are mounted as an extension to a house or other structure (a shed, a fence and other outbuildings). Usually they are used for growing seedlings. Single-slope options occupy little space and are perhaps the most inexpensive in building materials. Such a structure should be placed so that the ramp looks towards the south. To cover a pitched roof, it is recommended to use glass or plastic.

Pyramidal

Gardeners believe that the pyramidal design can increase the yield of plant crops. This form creates a favorable microclimate for plants. In such a structure, the base is a square with equal sides. Frame ribs connect in the center of the base. The entrance to the building is located from the north. If you put a dying plant in a pyramid greenhouse, then it will certainly recover in time. It is good to germinate seeds, it is beneficial to grow seedlings.

Did you know? Experiments with replicas of small pyramid structures showed their therapeutic effect and ability to store products. Water placed in such a design acquires a key taste, and plants watered by it give large yields.

The height and length of the pyramid are in a certain ratio - the side of the square at the base should be 1.57075 times the height of the structure, which is measured from the middle of the base to the point of intersection of the side faces. It should be taken into account that the height of the building must be such as to be able to carry out work in it, because the walls in this design are located at an angle.

On small private courtyards, experts recommend installing pyramids-greenhouses of the following sizes:

- height - 3.2 m;

- side of the square - 1.42 m;

- diagonal - 2 m.

Thus, the ratio of the diagonal of the base to the height will correspond to a "golden ratio" of 0.62.

How to build a greenhouse with your own hands from a tree

You can build a greenhouse yourself from tree trunks. Such a construction will be relevant and economical if it is possible to purchase the necessary material through forestry during sanitary deforestation. Consider a rectangular construction with a gable roof, covered with plastic film.

Preparatory stage

It is necessary to prepare well for the construction of the greenhouse so that during the construction process there is no need to do alterations.

Did you know? A large contribution to the development of Russian greenhouses was made by a simple peasant from the Klinsky okrug near Moscow. He developed new stove-heated greenhouse constructions for growing wedge cucumbers.

Size calculation

The design parameters depend on the desired plant capacity, the selected type of construction, size and characteristics of the site. At a rectangular greenhouse, it is necessary to make accurate right angles in order to then select and trim the material correctly in size.

When calculating the dimensions for a homemade column greenhouse, the following should be considered:

- Support racks must be dug half a meter into the ground around the perimeter in increments of 1.6 m.

- The height of the walls of the building for tall cucumbers and tomatoes should be 2 m. This means that you need to take trunks 2.5 m long.

- For a gable roof in the middle of the greenhouse, it will be necessary to make a row of slightly greater height (80 cm) with a step of 2.5 m, so for the middle row take trunks 3.3 m long.

- At the ends, intermediate columns should be added so that the film swells less from air currents.

- On the poles around the perimeter and in the middle, wooden trunks are laid on which the roof beams will rest. These beams will need to be arranged in 0.8 m increments. This corresponds exactly to the width between the rows of cucumbers and tomatoes, and also helps the greenhouse roof withstand winter snowfalls.

- The greenhouse will be covered with two layers of film on the roof and on all sides. It is recommended to lay the thickest and strongest layer on the top layer of the roof.

- In a small building make 1 door at the end. In a large greenhouse, it is better to make two moves - one from each end.

Video: building a greenhouse made of wood

Choose a tree species

The most suitable for the construction of greenhouses are trunks of conifers - pine, larch, spruce. An excellent choice for racks would be larch. This tree is resistant to moisture and decay. The most affordable is usually a pine. Oak, hornbeam, beech, teak are also suitable, but they are not the easiest to process, because they have a high density.

Important! You should choose a well-dried tree (no more than 22% moisture) and abandon the use of material with traces of rot or the results of vital activity of wood-boring bugs, without cracks.

You can use the trunks of a suitable size, or you can buy a ready-made bar of the necessary parameters. For small buildings with a width of not more than 3 m, a 5 × 5 cm beam is enough. For load-bearing racks of structures more than 6 m wide, it is better to take round logs with a section of 6–7 cm or a beam of 8 × 8 cm.

Seat selection

The wooden structure should be where rainwater is not collected. The groundwater level should also not be closer than recommended for crops grown in the greenhouse. It is best if it will be in an elevated place. It is desirable that it be smooth. The greenhouse construction should stand so that the rows of cultivated plants are located from south to north - this is necessary for better illumination of plantings by the sun. There should be no trees or buildings near the greenhouse that can cast a shadow over it.

The greenhouse construction should stand so that the rows of cultivated plants are located from south to north - this is necessary for better illumination of plantings by the sun. There should be no trees or buildings near the greenhouse that can cast a shadow over it.

Step-by-step manufacturing instructions

When everything is thought out and prepared, you can proceed directly to the construction of the greenhouse itself.

Important! It is very important how to plan racks. To correctly make the markup, you need to measure not only the length and width of different sides, but also the diagonals. At a rectangular greenhouse, it is necessary to make accurate right angles in order to then select and trim the material correctly in size.

Foundation

For a columnar greenhouse, a tree is dug into the ground half a meter in depth. This is best done with a drill. The hole makes 15 cm more than the thickness of the racks, and the depth is a little more than half a meter. Crushed stone is poured to the bottom, a rack is installed and a backwash is made with crushed stone or poured with concrete. The stand is moved a little so that the concrete fills everything, and it is necessary to level it. In dense soil, you can simply drive a rack into the ground by drilling a slightly smaller hole.

Frame

Step-by-step wood construction is done as follows:

- Carefully mark the installation locations of the racks.

- Wooden trunks are dug 0.5 m into the ground with a pitch of 1.6 m, not forgetting to dig in the intermediate end supports.

- They dig in the middle row of racks in increments of 2.5 m.

- On top of the racks, wooden trunks and roof beams are mounted, hammering them with nails.

Did you know? Even the ancient Romans used greenhouses covered with mica to grow exotic tropical plants imported from southern countries.

Wooden greenhouse coating

To cover a wooden frame, it is best to take a light-stabilized film 9 m wide. The roof is covered in 2 layers. The first layer is made of a film 100-120 microns thick on top of the beams and fixed over stretched cables. This fixation allows the film to remain intact, insulate well and serve longer. For the second layer, a thinner film (0.6–0.8 mm) is taken and knocked down from below with shingles and nails. Thus, an air gap is obtained, which does not allow warm air to leave the greenhouse. The walls around the perimeter of the greenhouse are also covered with a film 0.6–0.8 mm thick and 2.5 m wide on both sides of the perimeter posts, fastened with shingles and nails, and its ends are dug into the ground. Do not forget to make a door or canopy for entry at the end.

Thus, an air gap is obtained, which does not allow warm air to leave the greenhouse. The walls around the perimeter of the greenhouse are also covered with a film 0.6–0.8 mm thick and 2.5 m wide on both sides of the perimeter posts, fastened with shingles and nails, and its ends are dug into the ground. Do not forget to make a door or canopy for entry at the end.

You can build a wooden greenhouse with your own hands, having a simple set of tools for working with wood. With such a construction, you can choose the most optimal sizes yourself and save on the purchase of the finished product.